Features

Take your maintenance from good to great

Spanner is a complete Planned Maintenance System that allows you to plan, work, and report on all maintenance that takes place on board your vessel.

With usability as our core focus, your crew will be able to get their work done quickly and effectively.

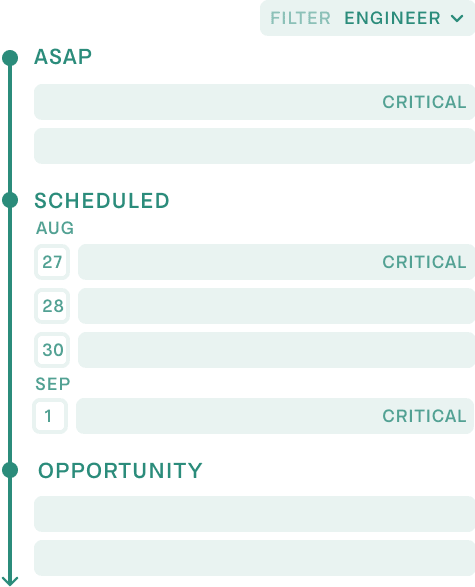

Effective planning

The full maintenance picture

Spanner splits planning from work so you can see the full story. Focus on good categorisation and structure, ideal maintenance schedules, and how much you need of everything to run a safe ship.

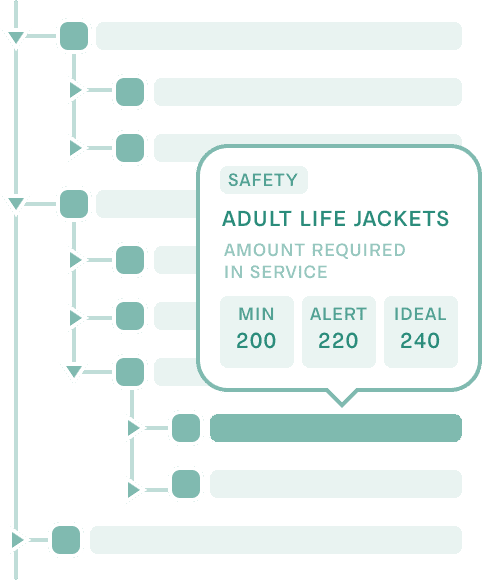

Assets follow the plan

Working with assets in Spanner is simple. Because assets follow the ship’s maintenance plan, adding new assets (and replacing old ones with new) can be as simple as adding a serial number or expiry date. The maintenance schedule is applied automatically.

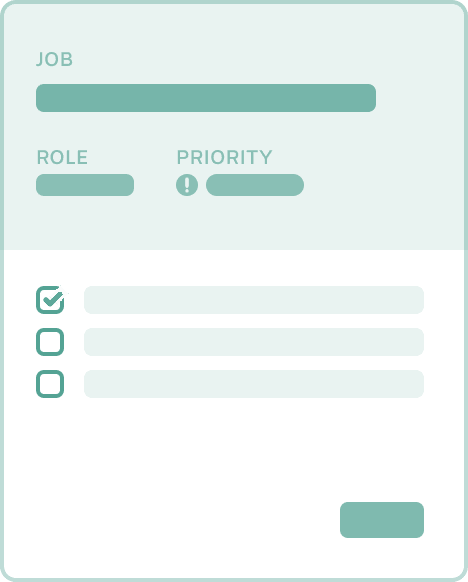

Work ready job cards

Step by step instructions? Installation notes? Precise specifications? If it’s in the plan, it’s on the job card, and you’ll have everything you need to get the job done.

Environment and ethics

Spanner is dedicated to transparency when it comes to the environment, sustainability, human rights, and privacy.

Our position statement

Digital tools can be used for surveillance and labour abuses. Spanner does not record or enforce data that could be used to push crew to work beyond their labour obligations. We’re for optimising maintenance, not optimising how much work you can squeeze out of employees.

No tracking

Except for the minimal amount of user information necessary to create user accounts, we don’t collect or share any of your personal information.

Tech Specs

Feature breakdown/specifications

Dot points. Nitty gritty. For the details at a glance.

Flexible plan

Your vessel’s requirements plan keeps you accountable but can be changed whenever your equipment and procedures do. Update the plan yourself, or call on our support team when you need to.

Complex Components

Requirements can be planned out to be single pieces of equipment, or complex equipment made up of a range of components, each component having its own maintenance schedule and history.